Starting a new commercial build is a massive undertaking, and its success hinges on a powerful and safe electrical system. For any developer, understanding the complexities of commercial new construction electrical work is essential for a functional, compliant, and future-ready building. Let me explain what you need to know to power your project successfully.

Contents

What Commercial New Construction Electrical Work Involves

When you’re planning a new commercial build, the electrical system is far more complex than residential work. Here’s what it involves:

Key Components of Commercial New Construction Electrical:

- Higher Voltage Requirements – Commercial systems operate at 120V-480V compared to residential 120V-240V.

- Three-Phase Power Distribution – More efficient power delivery for heavy equipment and large-scale operations.

- Comprehensive Load Calculations – Detailed planning per NEC Article 220 to ensure your electrical service can handle current and future demands.

- Stricter Code Compliance – Must meet National Electrical Code (NEC), local amendments, and OSHA safety standards.

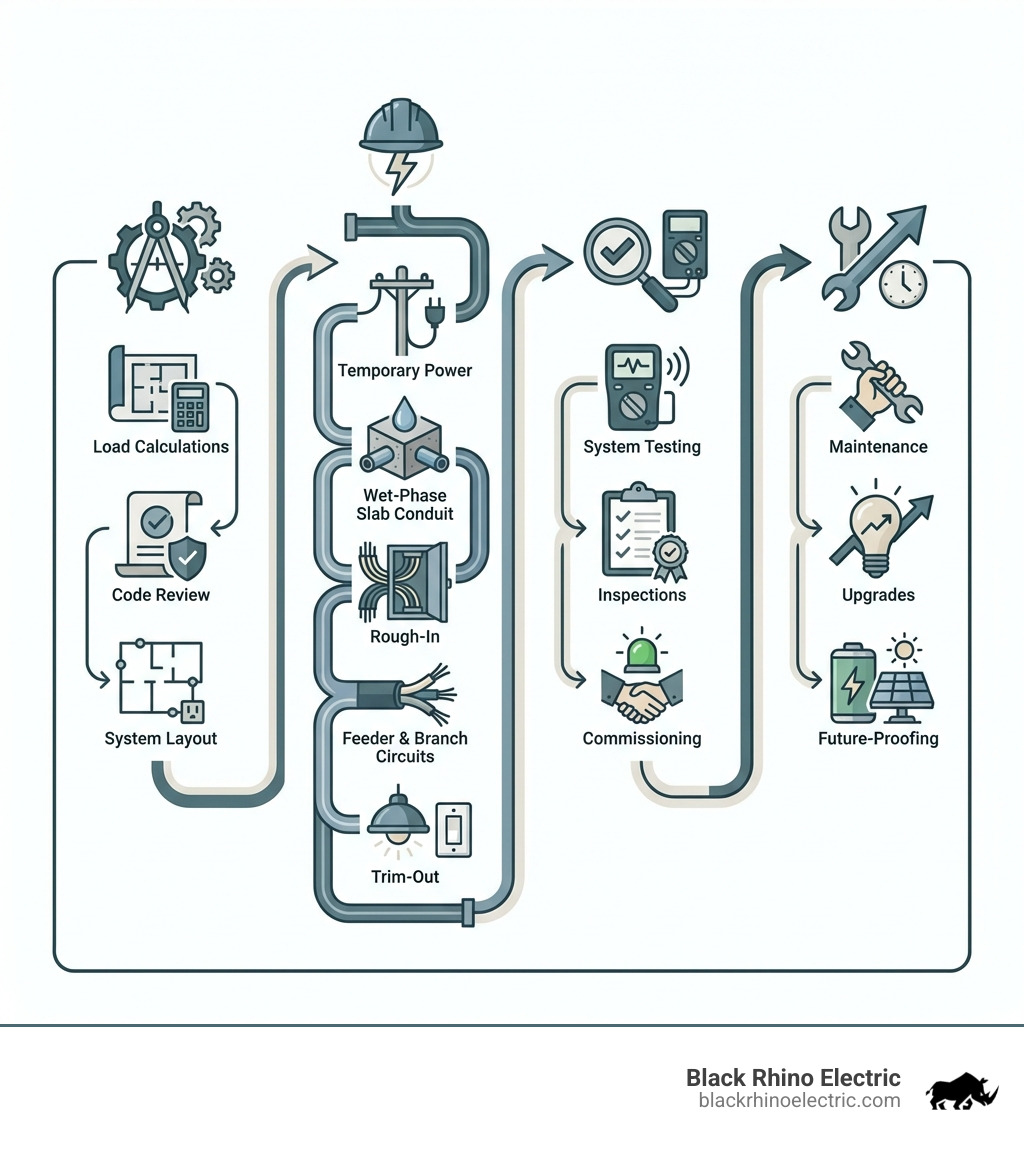

- Multi-Phase Installation Process – From temporary power and slab conduit through rough-in, feeder installation, trim-out, and final testing.

- Specialized Systems – Integration of emergency power, fire alarms, security systems, data cabling, and smart building controls.

- Permitting and Inspections – Multiple inspection phases (rough-in, final, fire/life safety) required before occupancy.

The difference isn’t just scale—it’s complexity, regulatory requirements, and the specialized expertise needed to power entire business operations. Commercial electricians often require up to 8,000 apprenticeship hours to work independently on these complex systems.

You know what? Proper electrical planning prevents expensive retrofits and ensures your building meets both current and future needs. With the 2026 NEC set to introduce expanded requirements for EV charging and renewables, forward-thinking design is more important than ever.

Blueprint for Power: Planning, Design, and Code Compliance

This is where it all begins. Honestly, proper planning is the single most important factor in preventing costly rework and ensuring your building’s electrical system can handle both current demands and future growth. It’s about designing a robust electrical backbone custom to your business.

Commercial vs. Residential: More Than Just Scale

The distinction between commercial and residential electrical systems is profound, with fundamental differences in power delivery, safety standards, and operational demands.

Here’s a quick breakdown of the primary differences:

| Feature | Commercial Electrical Systems | Residential Electrical Systems |

|---|---|---|

| Power Type | Typically three-phase power for efficiency and capacity. | Commonly single-phase systems for household appliances. |

| Voltage | Higher voltages, ranging from 120V to 480V. | Lower voltages, typically 120V to 240V. |

| Wiring Methods | Often uses metal conduits and raceways for durability, safety, and accessibility. | Primarily uses Romex (NM cable) run through wall cavities. |

| Code Complexity | Stricter National Electrical Code (NEC) requirements and local amendments. | Standard NEC applications, generally less complex. |

| Load Demands | Powers heavy machinery, complex HVAC, and concentrated electrical needs for many occupants. | Powers standard household appliances and lighting. |

| Electrician Training | Requires extensive specialized training, often 4,000-8,000 apprenticeship hours. | General electrical training, though still rigorous, is less specialized. |

In commercial settings, the need for efficiency and capacity is paramount. Three-phase power, for instance, provides a more constant and balanced power supply, which is ideal for motors and heavy equipment often found in businesses. Our licensed electricians in Weber County are specifically trained to handle these higher voltages and complex configurations, ensuring that your commercial property is powered safely and efficiently.

The Critical Role of Load Calculations and Design

Designing an electrical system for a new commercial building starts with meticulous planning. This isn’t a “guesstimate” situation; it’s a precise science called load calculation. We carefully determine the total power needed for everything from basic lighting and HVAC to specialized equipment, machinery, and even future expansion.

The National Electrical Code (NEC) provides the guidelines for these calculations, primarily in Article 220 (soon to be reorganized as Article 120 in the 2026 NEC). This article outlines how to calculate service and feeder loads, ensuring the system can handle both continuous and non-continuous loads. For example, feeders must be capable of supplying at least 125% of continuous loads and 100% of non-continuous loads. This extra capacity is crucial for safety and system longevity.

Panel sizing, which involves selecting the right electrical panels and meters for your building, directly follows these load calculations. We ensure your main electrical panel, sub-panels, and circuit breakers are appropriately sized to safely distribute power throughout the entire facility. This also means considering power distribution methods that are both efficient and accessible.

Honestly, one of the biggest mistakes we see is underestimating future needs. That’s why we always emphasize future-proofing and scalability in our designs. We consider potential growth, new technology, and increased energy demands. This might mean installing dedicated circuits for major appliances or machines based on their load, use, and function, or even reserving space in electrical panels for future additions like EV charging stations, which are becoming increasingly common in commercial properties. For more about comprehensive planning, check out our guide on Commercial Electrician Services: What You Need to Know.

Navigating the labyrinth of electrical codes, permits, and inspections can feel overwhelming. But here’s the thing: it’s non-negotiable for safety, compliance, and ensuring your business can legally operate.

The cornerstone of electrical safety in the U.S. is The National Electrical Code (NEC), also known as NFPA 70. This comprehensive document sets the baseline for electrical design and safety, and it’s updated every three years to incorporate new technologies and safety practices. Beyond the NEC, local jurisdictions in Utah, including Weber County, often adopt their own amendments that can add specific requirements. The Authority Having Jurisdiction (AHJ)—usually your local building department—is the ultimate interpreter and enforcer of these codes.

Securing the necessary permits is the first official step. This ensures your project is reviewed and approved before any work begins. Throughout the construction, your project will undergo multiple inspections:

- Rough-in Inspection: Conducted after the wiring, conduits, and boxes are installed but before walls and ceilings are closed up. This allows inspectors to verify proper installation and code compliance.

- Final Inspection: Performed after all electrical work is complete, fixtures are installed, and the system is ready for energization.

- Fire/Life Safety Inspection: Often a separate inspection, focusing on emergency lighting, exit signs, fire alarm systems, and other critical life safety components.

Passing these inspections is critical for receiving your occupancy certificate, which allows you to legally open your business. Failing to comply with codes can lead to costly delays, fines, and even necessitate Code Violation Repairs. Moreover, OSHA standards are directly tied to the NEC, meaning many of OSHA’s basic workplace safety requirements match NEC codes, underscoring the importance of strict adherence. We ensure all our commercial new construction projects in Ogden and surrounding areas meet these stringent requirements.

From Rough-In to Power-On: The Commercial New Construction Electrical Process

Once the blueprint is approved, the real work begins. The installation process for a commercial new construction electrical system is a multi-phase operation requiring meticulous coordination with other trades and an unwavering focus on safety. Here’s the thing: every step, from laying the first conduit to final testing, is crucial.

Key Phases and Components of a Commercial Installation

The installation of a commercial electrical system is a carefully orchestrated process, often involving complex coordination with other trades like plumbers and HVAC technicians.

Here are the typical phases and essential components:

- Temporary Power: Before anything else, a temporary power supply is established to energize the construction site, allowing other crews to use tools and lighting.

- Wet-Phase Slab Conduit: This is one of the earliest electrical tasks. Conduits are laid in trenches and within concrete slabs before the foundation is poured, channeling electricity throughout the property. This requires precise coordination with structural teams.

- Rough-In: Once the building’s shell is up, our team installs conduits, raceways, and electrical boxes throughout the walls and ceilings, before drywall is installed. Commercial wiring often runs through metal conduits for protection and accessibility, unlike residential wiring.

- Feeder & Branch Circuit Wiring: Feeders, the main electrical distribution network, are installed to carry power from the service entrance to the main distribution panels. Branch circuits then extend from these panels to power individual outlets, lights, and equipment.

- Equipment Installation: This phase involves setting up major electrical components like Electrical Panels and Meters, switchgear, transformers, and large machinery connections.

- Trim-Out: After walls are finished, devices like switches, outlets, light fixtures, and covers are installed. This also includes connecting low-voltage systems like data, communication, security, and fire alarm systems.

- Testing & Commissioning: Once the installation is complete, the entire system undergoes rigorous testing to ensure everything functions correctly, safely, and efficiently before the building is handed over.

Essential components like robust lighting systems (including energy-efficient LEDs and emergency lighting), comprehensive power distribution via panels and circuit breakers, and critical emergency power systems (such as generators and uninterruptible power supplies or UPS) are integrated throughout these phases. Exit signs and emergency lighting are required in many commercial spaces and must have backup power sources like batteries or generators per NEC and life safety codes.

Essential Safety Protocols and Risk Management

Given the higher voltages and complex systems involved in commercial electrical work, safety is not just a priority—it’s paramount. We adhere to strict safety protocols and risk management strategies to protect our workers, other trades, and the future occupants of your building.

Key safety measures include:

- OSHA standards Compliance: We strictly follow all Occupational Safety and Health Administration (OSHA) regulations, many of which are directly tied to NEC requirements, ensuring a safe working environment.

- personal protective equipment (PPE): Our electricians always use appropriate PPE, including insulated gloves, eye protection, and flame-resistant clothing, to mitigate risks associated with electrical work.

- Lockout/Tagout Procedures: Before any work begins on energized equipment, strict lockout/tagout procedures are implemented to ensure power is completely de-energized and cannot be accidentally re-energized.

- Arc Flash Studies: For certain high-voltage systems, we conduct arc flash studies to identify potential hazards and determine the necessary safety boundaries and PPE.

- Site Safety Audits: Regular safety audits are performed to identify and address any potential hazards or non-compliance issues throughout the project.

- Fire Safety Systems: Beyond general electrical safety, we specialize in installing and integrating crucial fire safety components like fire alarms and emergency lighting systems. These systems are vital for property protection and occupant safety. For more on ensuring your property’s security, consider our Alarm Systems services.

Our commitment to safety means that every commercial new construction electrical project we undertake in Weber County is executed with the highest level of care and professionalism, minimizing risks and ensuring peace of mind.

Future-Proofing Your Build: Smart Tech and Maintenance

The commercial landscape is constantly evolving, and so are electrical systems. When we design and install your commercial new construction electrical system, we’re not just thinking about today—we’re thinking about tomorrow.

Emerging Trends:

- Smart Infrastructure and IoT Sensors: Integrating smart systems and Internet of Things (IoT) sensors allows for automated control, real-time monitoring of energy usage, and predictive maintenance. This can lead to significant operational efficiencies and cost savings.

- LED Lighting and Smart Controls: Modern commercial lighting systems, especially those utilizing LED technology and smart controls, can reduce lighting energy usage by up to 75% compared to traditional lighting. We design and install advanced lighting solutions that improve aesthetics, improve worker productivity, and cut energy bills.

- EV Charger Installation Electrician: With the rise of electric vehicles, integrating EV charging infrastructure is becoming a standard amenity for new commercial buildings. The 2026 NEC will introduce expanded requirements for this, making early planning essential. We’re experts in installing commercial EV charging stations in Ogden and throughout Weber County.

- Renewable Energy Integration: More businesses are looking to incorporate solar panels or other renewable energy sources. We can design electrical systems that seamlessly integrate these solutions, helping you achieve sustainability goals and potentially reduce long-term energy costs.

Post-Installation Services and Scalability:

Once your new commercial building is complete, our job isn’t over. Regular maintenance is crucial for the longevity, efficiency, and safety of your electrical system. This includes:

- Preventive Maintenance: Scheduled checks and servicing to prevent issues before they arise. This can involve thermal imaging to detect overheating connections, testing emergency systems, and tightening connections.

- Inspections: Beyond initial compliance inspections, regular checks ensure ongoing adherence to codes and optimal performance.

- Troubleshooting and Repair: Prompt identification and resolution of any electrical issues to minimize downtime.

- System Scalability: We design systems with spare capacity and accessible infrastructure, making future upgrades and expansions easier and less disruptive as your business grows. This is where The Role of a Commercial Electrician in Building Maintenance truly shines.

By focusing on these emerging trends and offering comprehensive post-installation support, we ensure your commercial electrical system in Weber County is not only robust and compliant but also adaptable and ready for the future.

Conclusion: Powering Your Project with Confidence

Successfully navigating commercial new construction electrical work requires expertise, precision, and a forward-thinking approach. From initial design and code compliance to future scalability, every detail matters. Partnering with a qualified and experienced team ensures your investment is safe, compliant, and built to last. At Black Rhino Electric, our licensed and insured contractors specialize in delivering comprehensive electrical solutions for new commercial projects across Weber County, managing every phase to ensure your new building is powered for success from day one.

Our customer-centric approach means transparent pricing, minimal disruption, and 24/7 availability for urgent needs, ensuring your local electrician in Ogden is just a call away. We’re committed to quality workmanship, code-compliant installations, and sustainable upgrades that slash energy costs and boost efficiency. Trusted by Weber County businesses, we turn electrical objectives into seamless, worry-free realities.

Ready to discuss your new construction project? Give our expert team a call at 801-810-4292 for a direct consultation. For a detailed estimate custom to your project’s needs, you can also Request a Free Quote online today.