Contents

Quick Answer: Your Aluminum Wiring Repair Options

If your home was built between the mid-1960s and mid-1970s, there’s a chance it contains aluminum wiring repair issues that could put your family at risk. Millions of American homes still have this outdated wiring, and knowing your options for addressing it is crucial for your safety and peace of mind.

Here’s what you need to know about fixing aluminum wiring in your home:

Three CPSC-Approved Solutions:

- COPALUM Crimp Connectors – Permanent repair using specialized cold-weld technology ($50-60 per outlet)

- AlumiConn Connectors – Set-screw copper pigtails for reliable connections (similar cost per outlet)

- Complete Copper Rewiring – Total replacement for maximum safety (most expensive but most permanent)

Warning Signs You Need Help:

- Flickering or dimming lights

- Warm or discolored outlet covers

- Burning plastic smell near switches

- Frequently tripped circuit breakers

The Bottom Line: Homes with aluminum wiring manufactured before 1972 are 55 times more likely to reach fire hazard conditions than copper-wired homes. This isn’t something to put off.

Here’s the thing: aluminum wiring was a popular cost-saving alternative during the copper shortage of the 1960s and early 1970s. Builders used it in roughly 2 million homes across the United States. But the material’s properties—high electrical resistance, oxidation, and thermal expansion—create dangerous loose connections over time.

The good news? You have proven repair options backed by the U.S. Consumer Product Safety Commission. The key is understanding which method makes sense for your home, your budget, and your long-term safety goals.

Let me explain what makes aluminum wiring dangerous, how to spot it in your home, and which repair method will give you the protection and peace of mind you deserve.

Understanding the Risks of Aluminum Wiring

When we talk about aluminum wiring repair, we’re mitigating a significant fire hazard. If your home in Ogden or anywhere in Weber County was built between 1965 and 1973, it’s crucial to know if you’re affected.

How to Identify Aluminum Wiring in Your Home

Here’s how to identify if your home has aluminum wiring:

- Age of Home: Built or expanded between 1965 and 1973.

- Wire Markings: Look for “AL,” “Aluminum,” or “Aluminum Alloy” on the cable’s outer jacket in unfinished basements or attics.

- Wire Color: The wires themselves are a distinct silvery-white, unlike reddish copper.

- Professional Evaluation: The safest method is to have a qualified Residential Electrician from Black Rhino Electric inspect your home. We can safely confirm the presence of aluminum wiring.

The Dangers Lurking Behind Your Walls

Let’s get straight to the point: this wiring is dangerous. The U.S. Consumer Product Safety Commission (CPSC) found that homes with pre-1972 aluminum wiring are 55 times more likely to have connections reach “Fire Hazard Conditions” than homes with copper. That’s a statistic that grabs your attention, isn’t it?

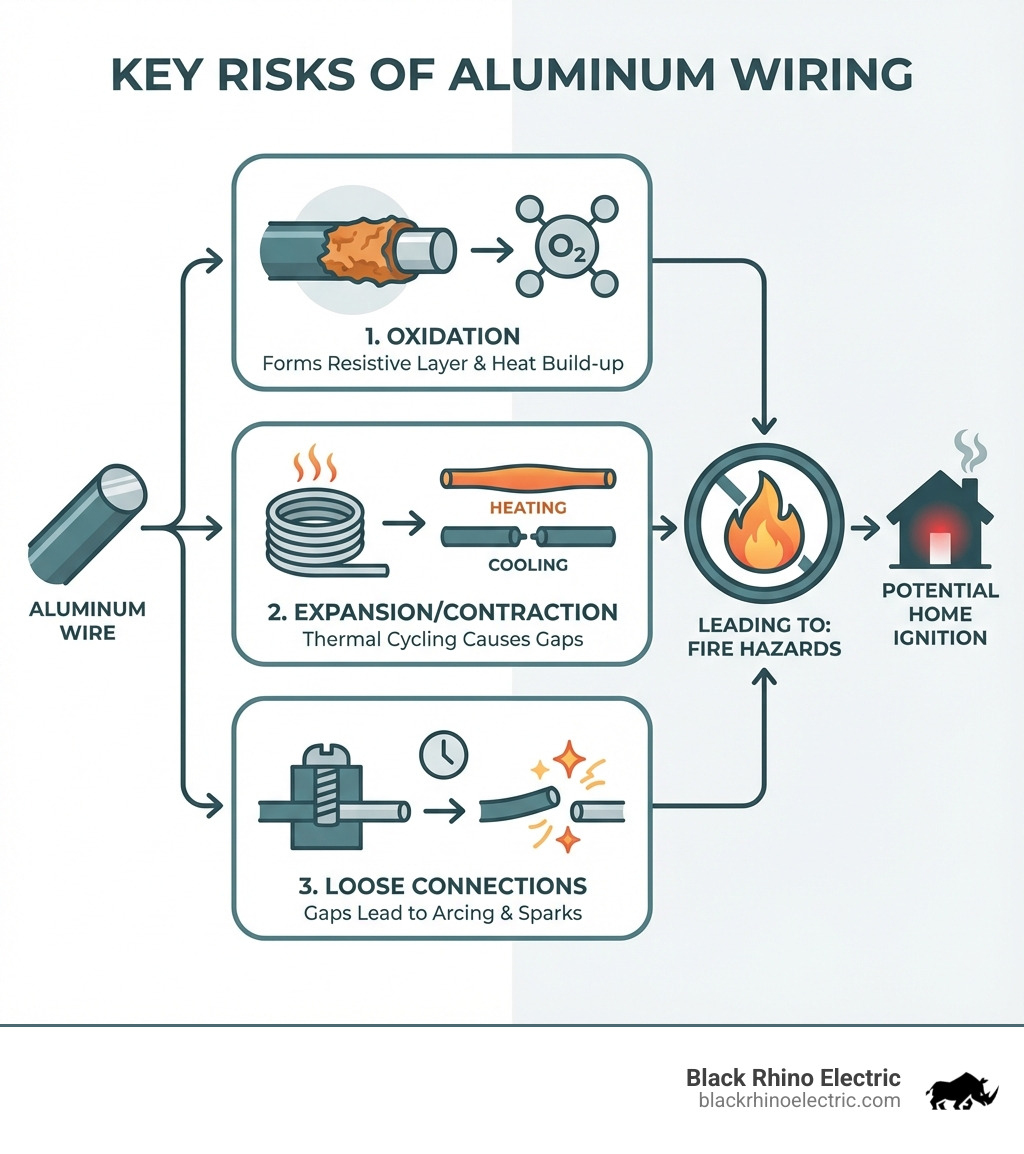

The problem boils down to a few key properties that cause connections to fail and dangerously overheat:

- Oxidation: When exposed to air, aluminum forms an oxide layer that acts as an electrical insulator. At connection points, this builds up resistance and heat.

- Thermal Expansion: Aluminum expands and contracts more than copper with temperature changes. This constant movement loosens connections over time, creating more resistance and heat in a vicious cycle.

- Softness and Corrosion: Aluminum is a softer metal that can deform or “creep” under pressure from terminal screws, loosening the connection. It can also corrode when connected to dissimilar metals, increasing resistance.

- Incompatibility: Many older outlets and switches were not designed for aluminum wire, making connections inherently unsafe.

Ignoring these issues can lead to property damage or worse. The CPSC has been warning about these dangers for decades, as detailed in their Safety Recommendations For Aluminum Wiring In Homes.

Warning Signs Your Wiring Needs Immediate Attention

Your home often gives subtle warnings before a major electrical issue. If you notice any of these signs in your Layton or Syracuse home, it’s time to call us immediately.

- Flickering or Dimming Lights: This can indicate loose or overheating connections.

- Warm or Discolored Outlet Covers: If switch plates are warm to the touch or show charring, it’s a serious red flag.

- Strange Buzzing Sounds: A buzzing or sizzling from an outlet or switch can indicate dangerous arcing.

- Smell of Burning Plastic: This is a critical emergency. Cut power to the area and call an electrician.

- Frequently Tripped Circuits: Frequent trips may signal underlying wiring problems beyond a simple overload.

These aren’t minor annoyances; they are your home’s way of telling you there’s a serious problem. While some are Common Electrical Issues a Residential Electrician Can Fix, with aluminum wiring, they demand immediate professional attention.

Your Guide to Aluminum Wiring Repair and Replacement

When you’re facing aluminum wiring, you have a few CPSC-approved options for aluminum wiring repair that can make your home safe. Most involve “pigtailing”—attaching a short piece of copper wire to the aluminum wire, so the device connects to stable copper instead of problematic aluminum.

CPSC-Approved Methods for Aluminum Wiring Repair

These are the gold standards for safety and reliability.

COPALUM Crimp Connectors:

This method, considered the most permanent repair by the CPSC, uses a specialized tool to apply immense pressure, creating a “cold weld” that permanently bonds the aluminum wire to a copper pigtail. This molecular bond eliminates the issues of oxidation and loosening. However, it requires a certified electrician with proprietary equipment.AlumiConn Connectors:

This CPSC-accepted alternative uses a small, insulated block with set screws to securely join aluminum and copper wires. It’s a reliable and permanent mechanical connection that performs very well. The main drawback is that the connectors are bulky and can be a tight fit in older, smaller electrical boxes.

Methods like using special “purple” twist-on wire nuts or simply installing CO/ALR-rated outlets are not considered acceptable permanent repairs by the CPSC, as they have a history of failure. For more details, you can review the CPSC guide on Repairing Aluminum Wiring. This is why using Licensed Electricians Ensuring Safety and Quality is non-negotiable.

Full Rewire: The Ultimate Solution

While pigtailing fixes the dangerous connection points, a full copper rewire eliminates the problem entirely by replacing all aluminum branch circuit wiring.

- Highest Safety Level: This is unequivocally the safest and most permanent solution.

- Long-Term Peace of Mind: You get a brand-new, modern electrical system with no worries about future aluminum-related issues.

- Increased Home Value: A full rewire is a major upgrade that adds significant value and makes your home easier to sell or insure.

A full rewire is the most expensive and disruptive option, as it involves opening walls. However, it’s the ideal time to do it during a major renovation or if insurance mandates it. You can learn more about the investment in our guide on the Cost to Rewire a House.

Comparing Aluminum Wiring Repair Options: Cost, Pros, and Cons

Choosing the right method involves weighing cost, effectiveness, and disruption. Costs can vary based on your home’s size and complexity in areas like Hooper or Riverdale.

| Feature | COPALUM Crimp Connectors | AlumiConn Connectors | Full Copper Rewire |

|---|---|---|---|

| CPSC Approval | Yes (highest recommendation) | Yes (accepted alternative) | Yes (best method if feasible) |

| Cost (per outlet/fixture) | ~$50 – $60 (can vary) | ~$50 – $60 (can vary) | N/A (whole-home cost) |

| Effectiveness | Permanent, molecular bond, highly reliable | Permanent, mechanical connection, very reliable | Ultimate, complete elimination of aluminum |

| Disruption | Low to Moderate (no major demolition) | Low to Moderate (no major demolition) | High (significant wall/ceiling demolition) |

| Pros | CPSC’s top choice, proven long-term safety, less disruptive than rewire. | CPSC-accepted, good alternative, less disruptive than rewire. | Eliminates all aluminum issues, highest safety, increases home value, complete peace of mind. |

| Cons | Requires specialized certified electrician and tools. | Connectors can be bulky, still leaves aluminum wire in walls. | Most expensive, most disruptive, extensive repairs needed. |

| Insurance Acceptance | Generally well-accepted. | Generally well-accepted. | Universally accepted, often preferred. |

Your choice will also be guided by local building codes and your homeowner’s insurance policy. Many insurers have strict requirements, sometimes mandating a specific CPSC-approved repair or even a full rewire. We ensure all our work in areas like Roy and West Haven meets these standards and the current National Electrical Code.

Securing Your Home and Making the Right Choice

Addressing aluminum wiring is a critical safety imperative, not just another home project. The risks are real, but the good news is that your home can be made safe with the right professional help.

The Critical Role of a Certified Electrician

Let’s be clear: this is not a DIY job. Attempting an aluminum wiring repair yourself is dangerous, can make the problem worse, and may void your home insurance. The nuances of working with aluminum and the precision required for CPSC-approved methods demand an expert. A Certified Electrician: Why Certification Matters is essential to:

- Accurately diagnose the scope of the issue.

- Recommend the most appropriate and cost-effective solution.

- Execute the repair flawlessly with the correct tools.

- Ensure all work is compliant with local and national codes for your safety and insurance.

Black Rhino Electric Expertise

From our base in Ogden, we proudly serve homeowners across Weber County and surrounding areas like Clearfield and Farmington. We specialize in addressing outdated wiring and are committed to making your home safe. Our customer-centric approach means transparent pricing, minimal disruption, and expert, reliable solutions.

Don’t wait for a warning sign to become a disaster—take proactive steps to secure your home’s electrical system today. For a professional assessment and reliable electrical repairs, trust the experts at Black Rhino Electric to get the job done right.

Contact us today for a free consultation—your go-to electrician in Ogden and Weber County for safe, swift, and superior service!